Nikon SB-5000 Flash Repair

As you may have read in my previous blog post here: https://t-e-o.net/nikon-reliability/ I have problems with my Nikon SB-5000 Flash.

After receiving quote of 221GBP for repair by Nikon, I decided to go-ahead and do flash xenon tube replacement by myself.

Below you can see full repair procedure which I have done on my Nikon SB-5000 flash to replace its Xenon Flash Tube.

Here it is flash before repair.

And the Flash Tube part itself. Part number is 1211Y and I have purchased it from ebay for 49.99$.

In old flashes Nikon SB-900 and Nikon SB-910 it was possible to replace only xenon tube for few dolars, but in SB-5000 whole assembly have to be replaced with genuine part.

Pots Which I used for collecting small parts and bolts during disassembly process.

After you rotate flash head at 90 degrees first step is to remove rubber seals on both sides covering set of bolts.

Do not afraid how you will glue them later, they were with sticky substance themselves so no glue was necessary.

For removal I used flat head screwdriver.

Removing Flash Rubber Seal on other side of the flash.

4 Bolts for removal from one side.

And 4 screws from other side.

I used tweezers to remove screws not to loose them as they were very tiny.

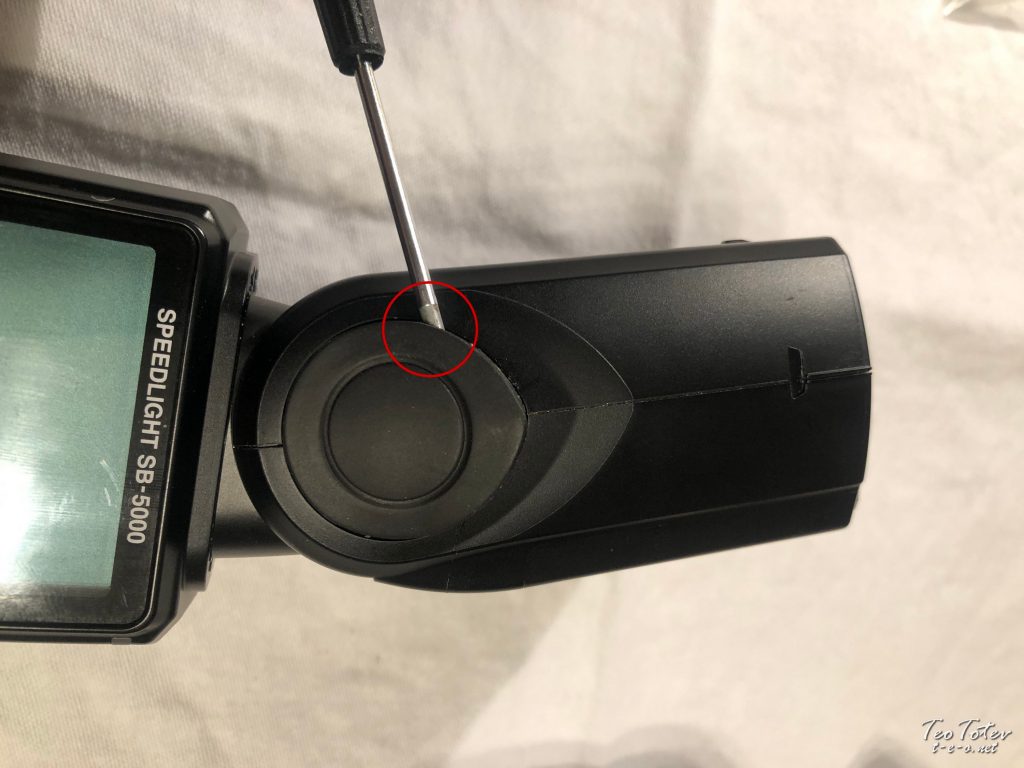

Spring button for flash tilting. You have to be careful with this one when you are disassembling and assembling back.

Side view of speedlight with screws removed.

Special three pongs / 3 wings screws which Nikon have put make SB 5000 disassembly difficult for average DIY.

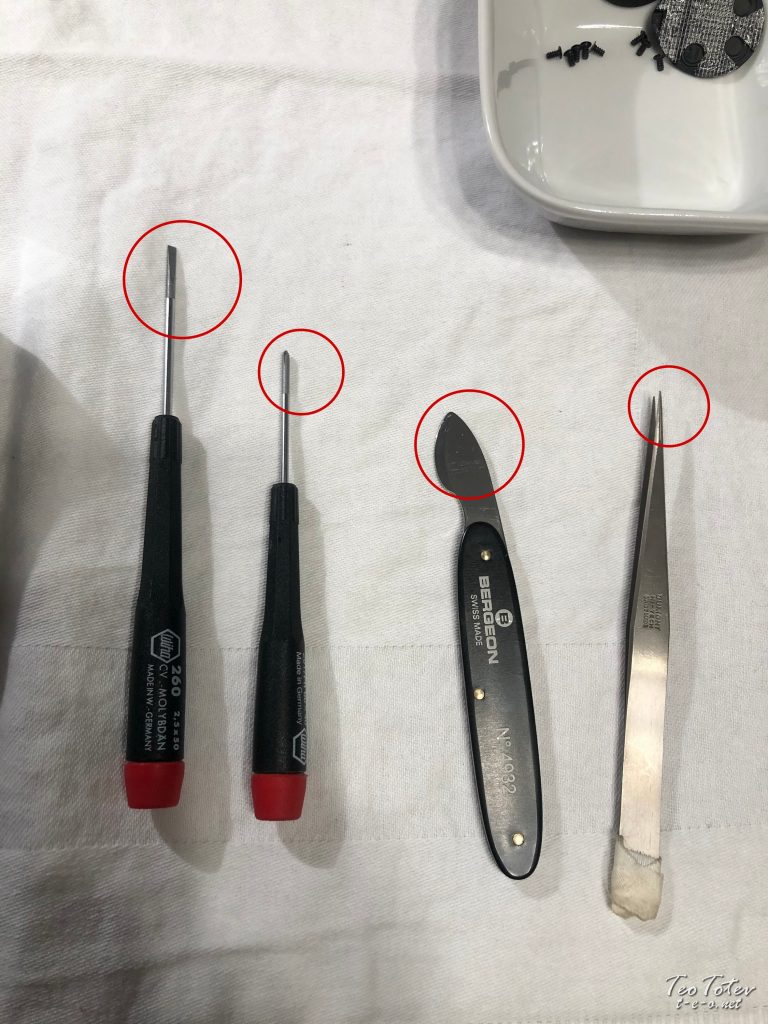

Tools used so far for repair.

Wiha Molybdan Screwdrivers

Bergeon N4932 Knife

Dumont Hi-Tech Tweezers

Using quality screwdrivers is essentials as one damaged screw can bring big troubles.

Closeup on 3 Pong Screw on Nikon Flash

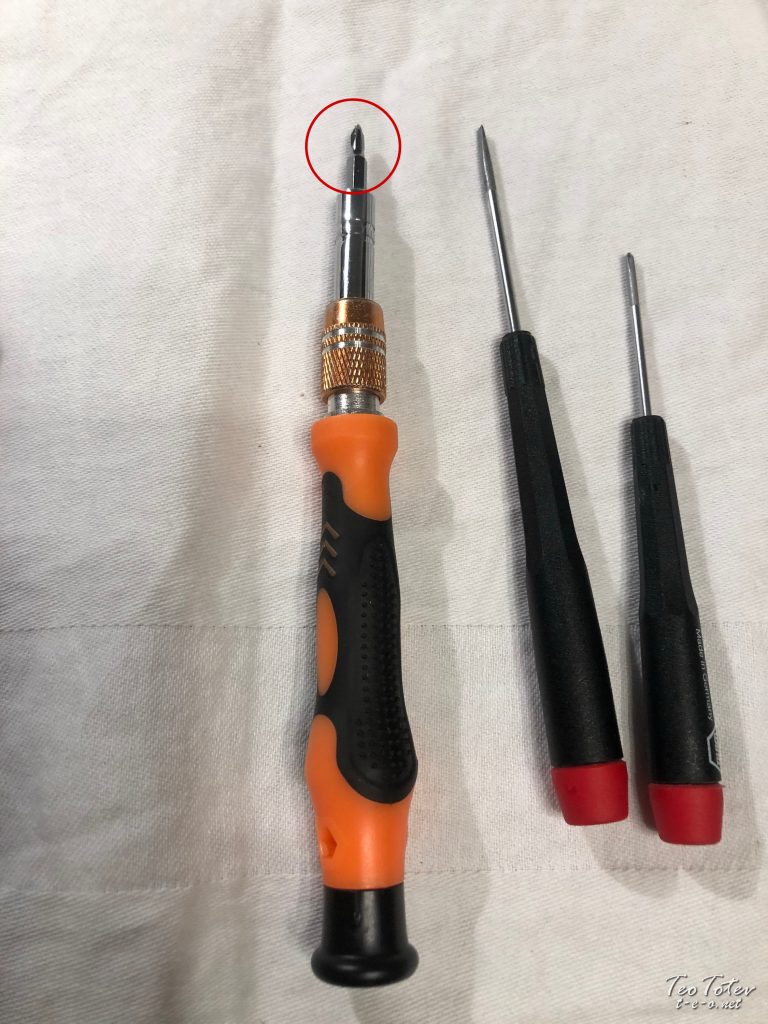

Zacro screwdriver which I used to unscrew 3 pong screws with size 3.0 tip.

Opening of flash with watch knife with blunt edge.

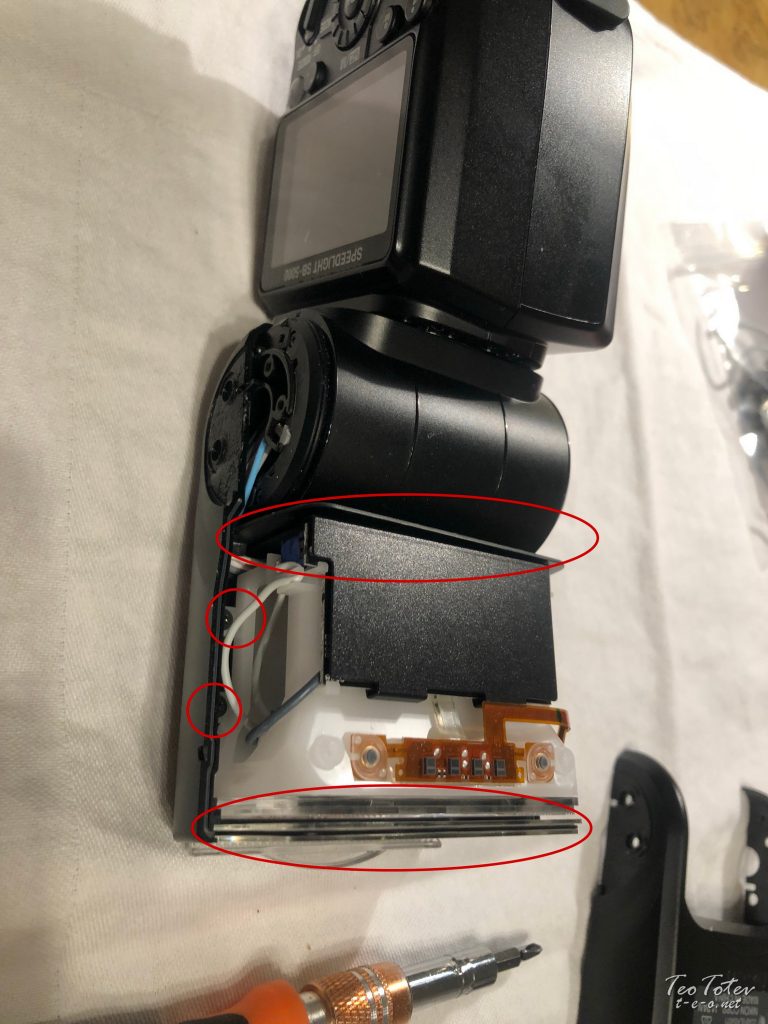

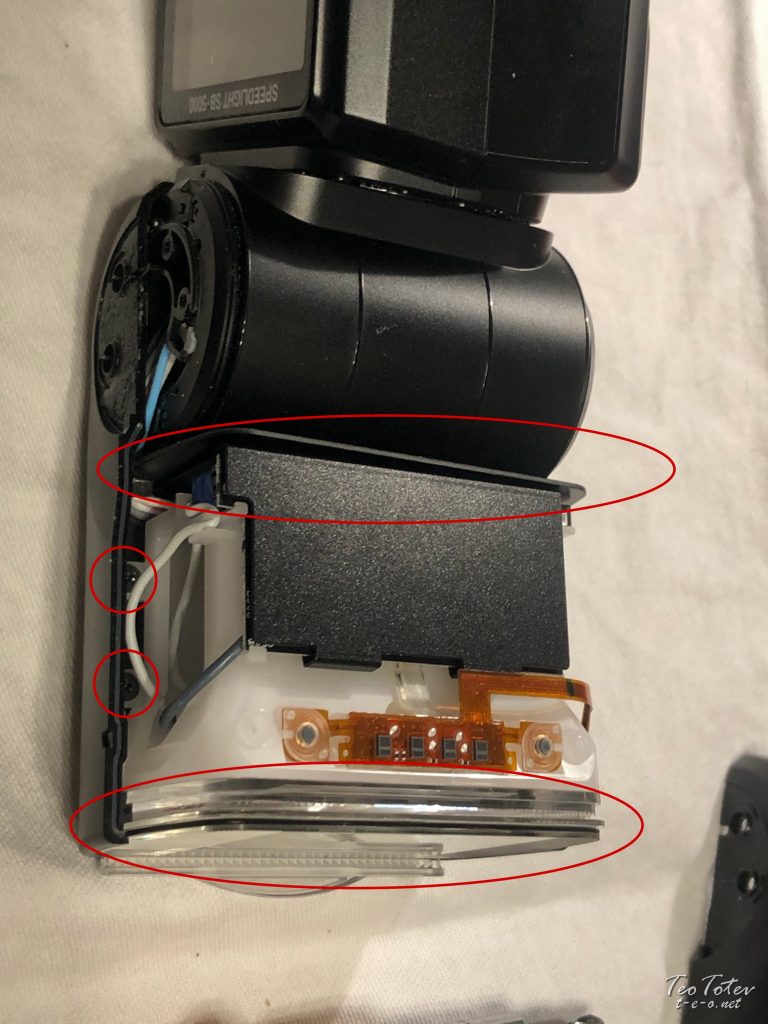

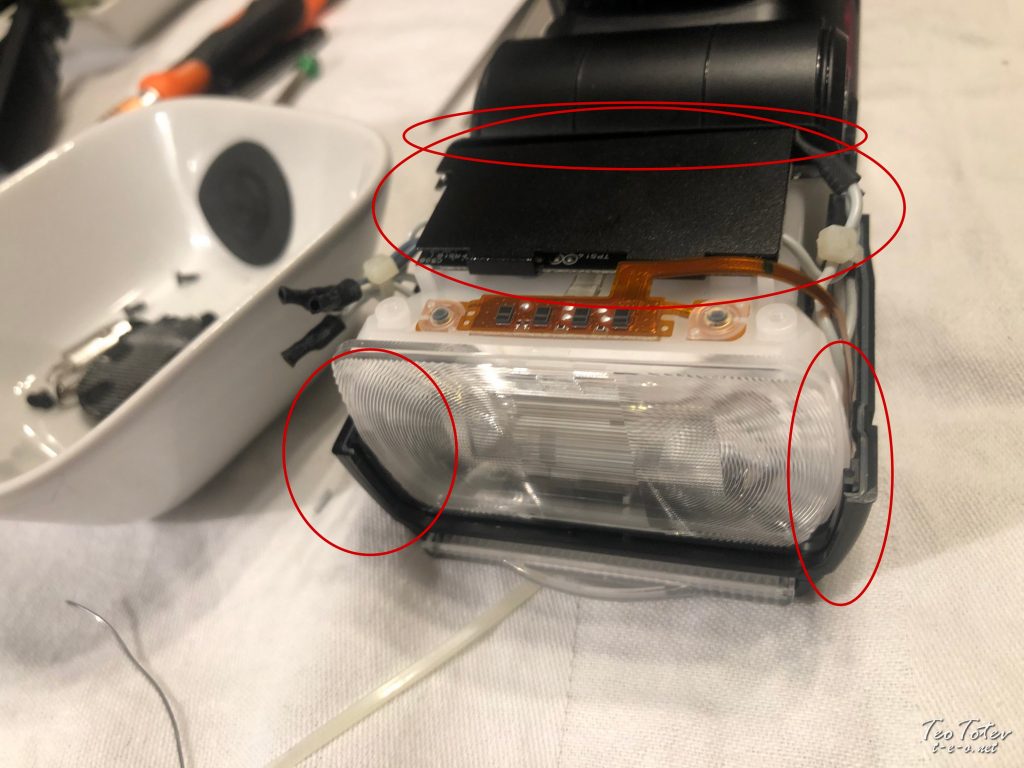

Keep special attention to orientation of freshnel glass /2 parts/ and also rear black divider. There are also 4 screws /2 on each side/.

A bit more closeup photo.

Be careful not to loose this metal plate which is spring loaded and act as release mechanism for tilting the flash.

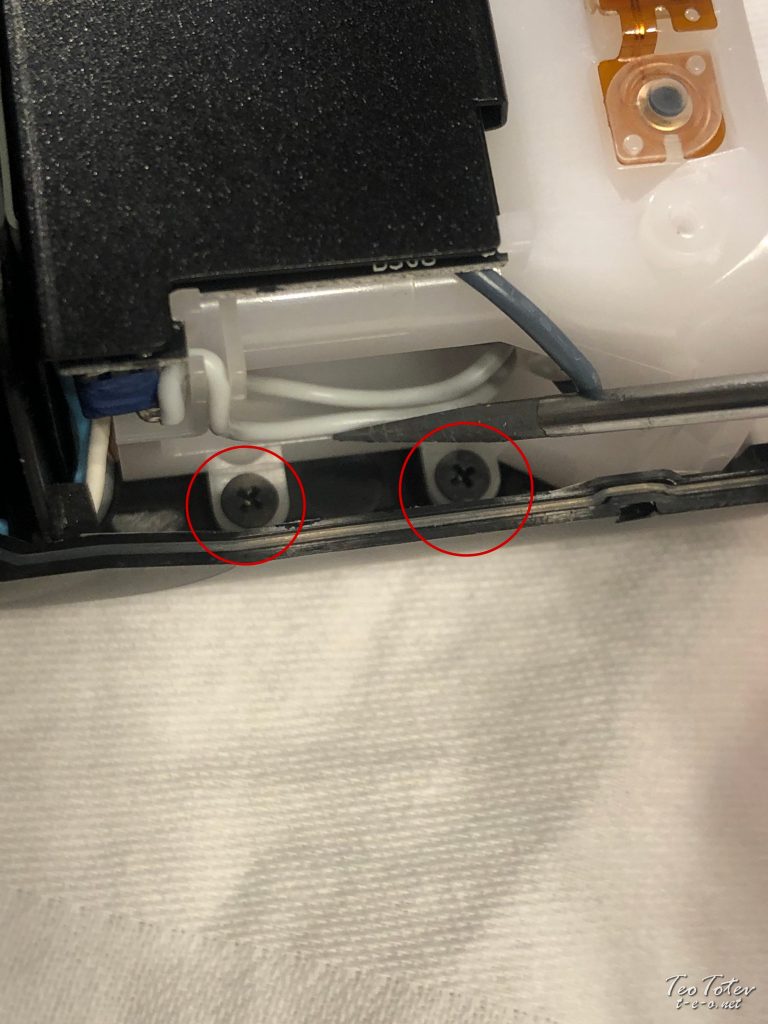

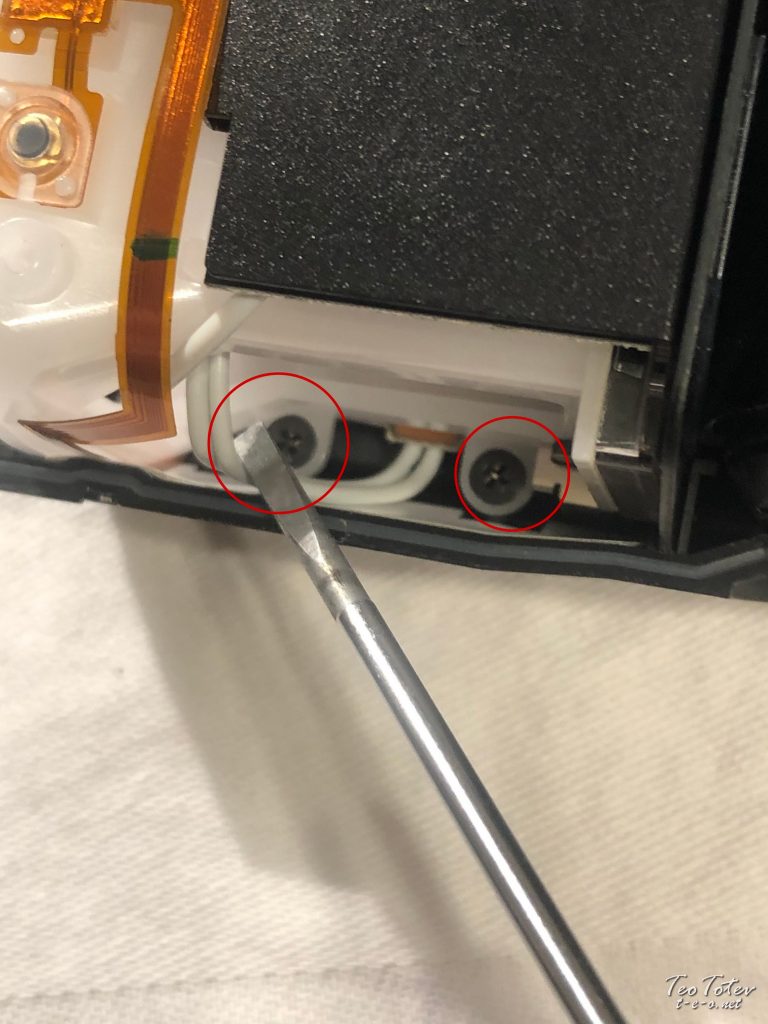

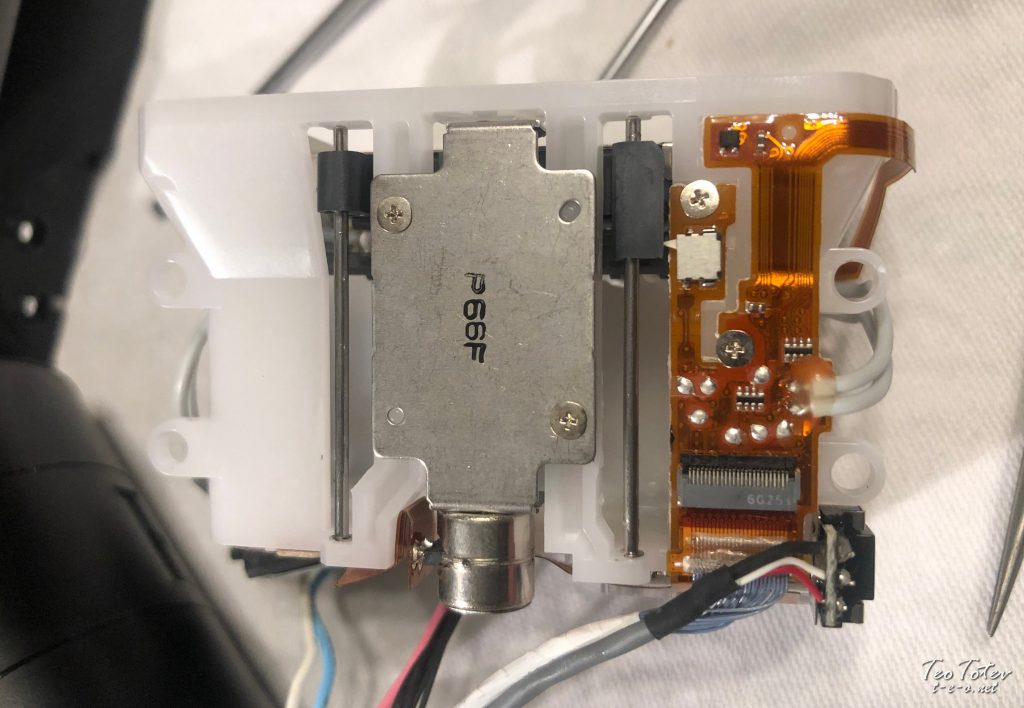

Here you can see side screws which are quite hidden inside the flash.

Other two on other side of flash.

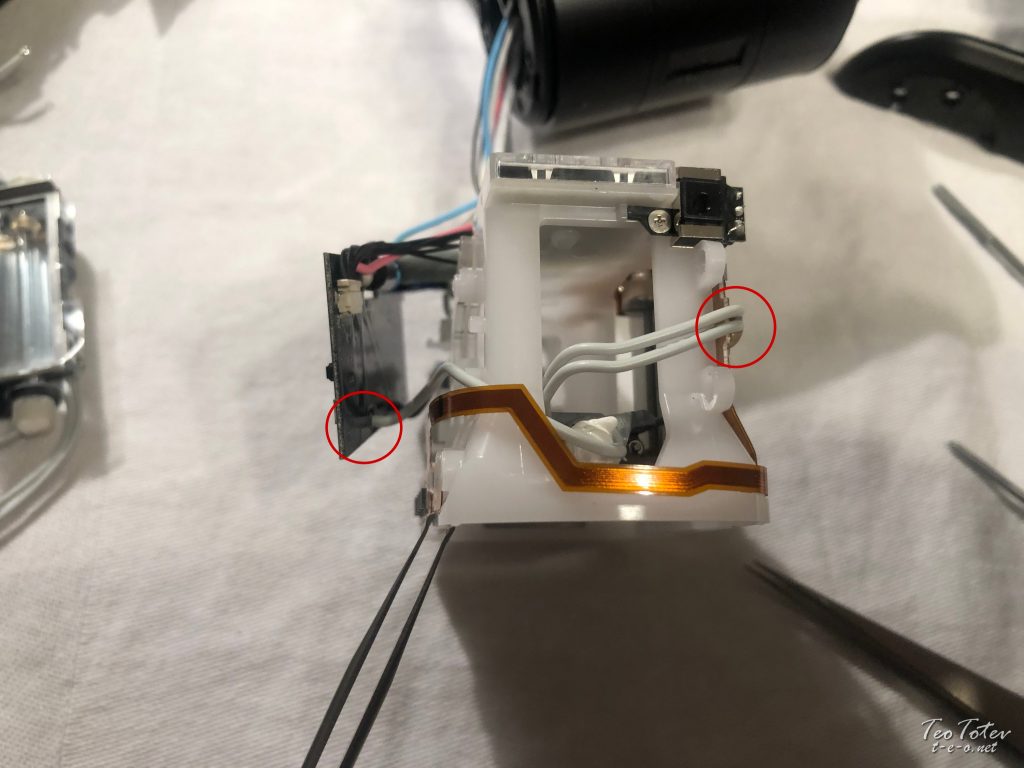

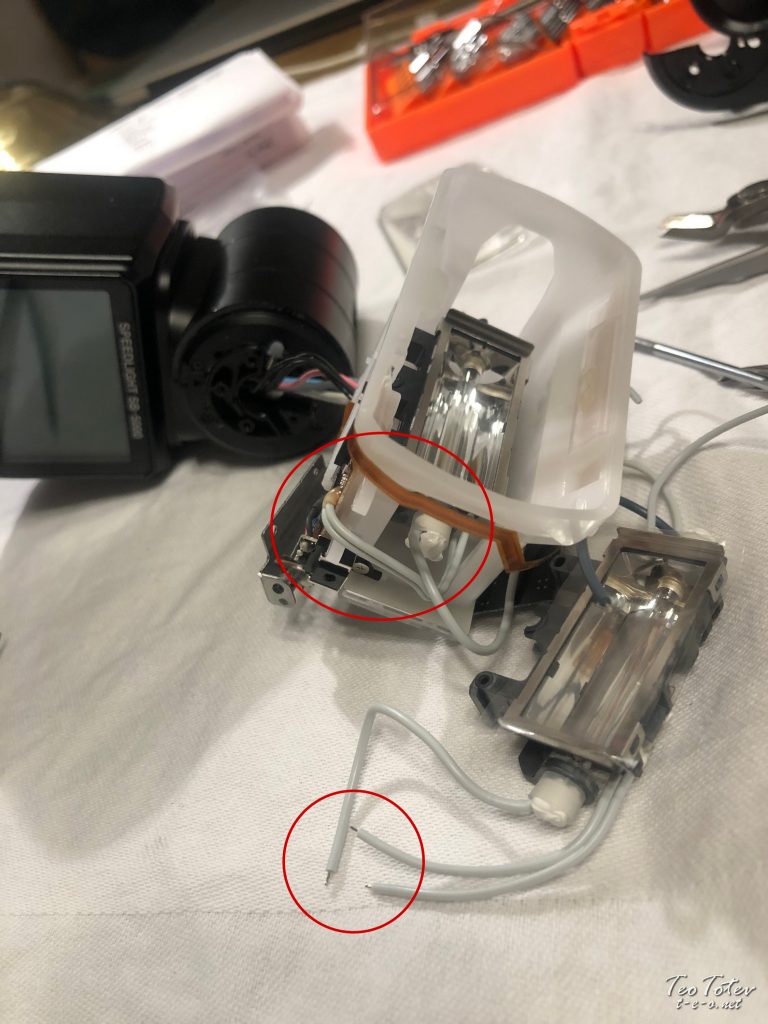

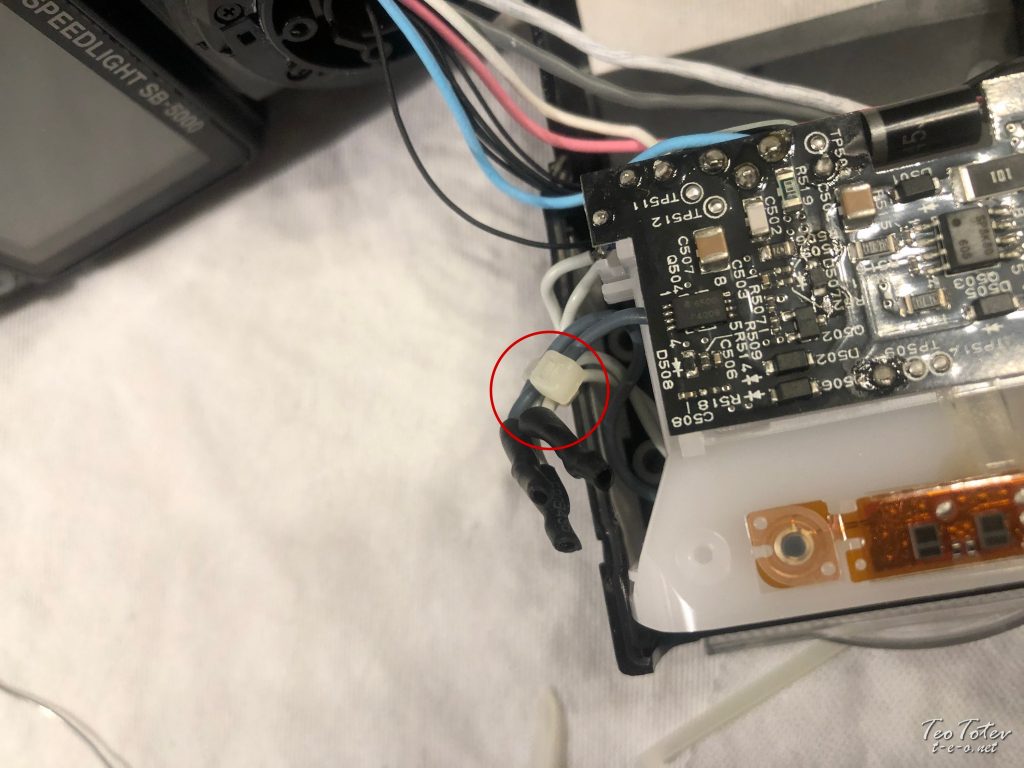

Keep attention to way barrier in middle of flash is put. Cables are passing where is red circle in photo above.

Next step is to remove sticky tape holding this isolation part around flash head and PCB.

In Lower end of photo you see sticky tape holding insulation part and and on left side are two screws holding motor of flash.

Top PCB of Nikon SB-5000 and marked screw which is holding it.

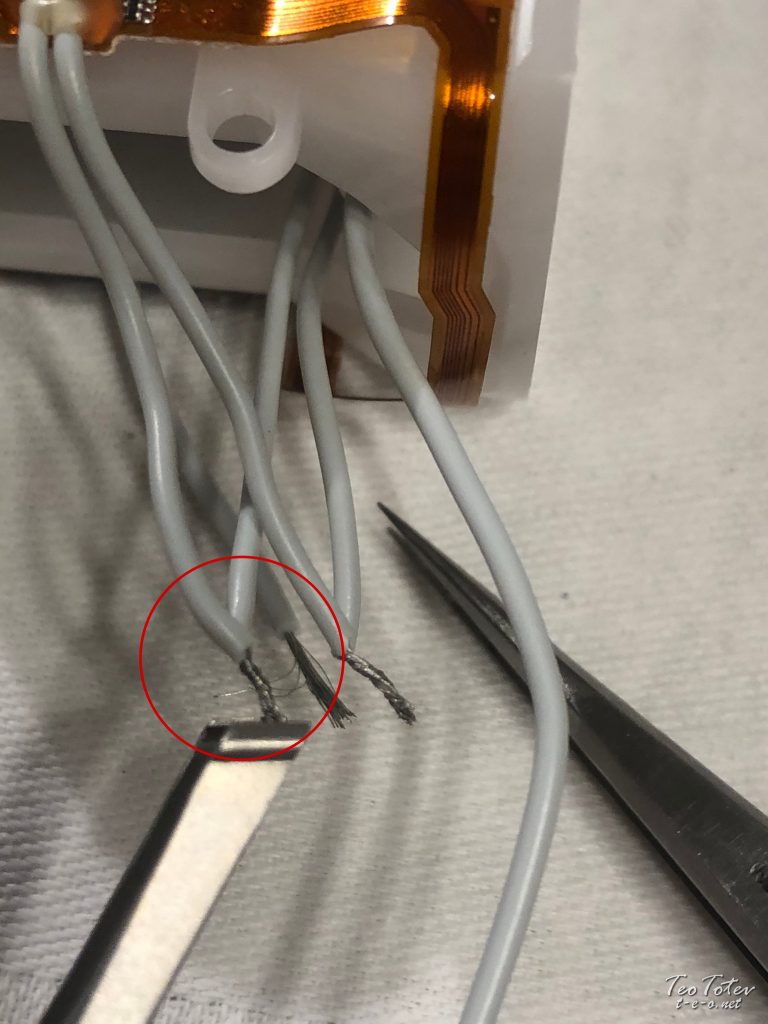

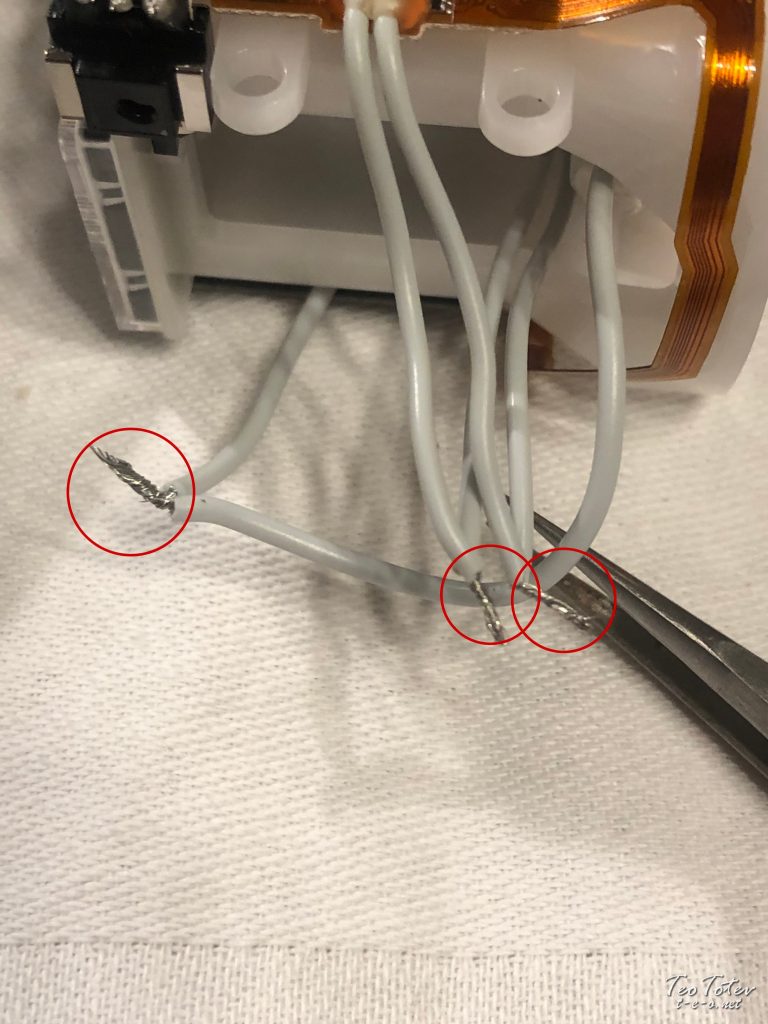

Take note where cabling are going from each side of flash tube.

There are total of 6 cables, 3 from each side.

Top view of assembly. In centre is motor and on right side are cables soldiered and glued on top. And this is next to very tiny chip.

Really bad news for re-soldiering and repair.

You can see motor assembly here with top screw already removed and removing second screw carefully with tweezers after unscrewing it.

These are screws and parts which I have in my part pot so far. Not a lot but it took me good time to reach this point.

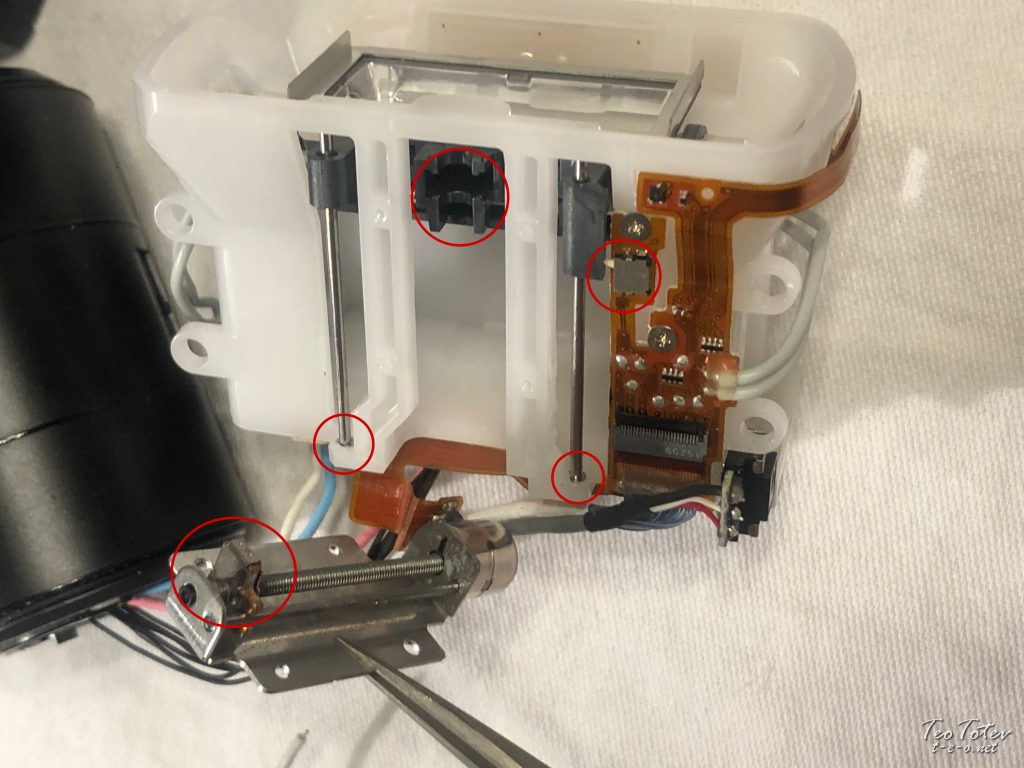

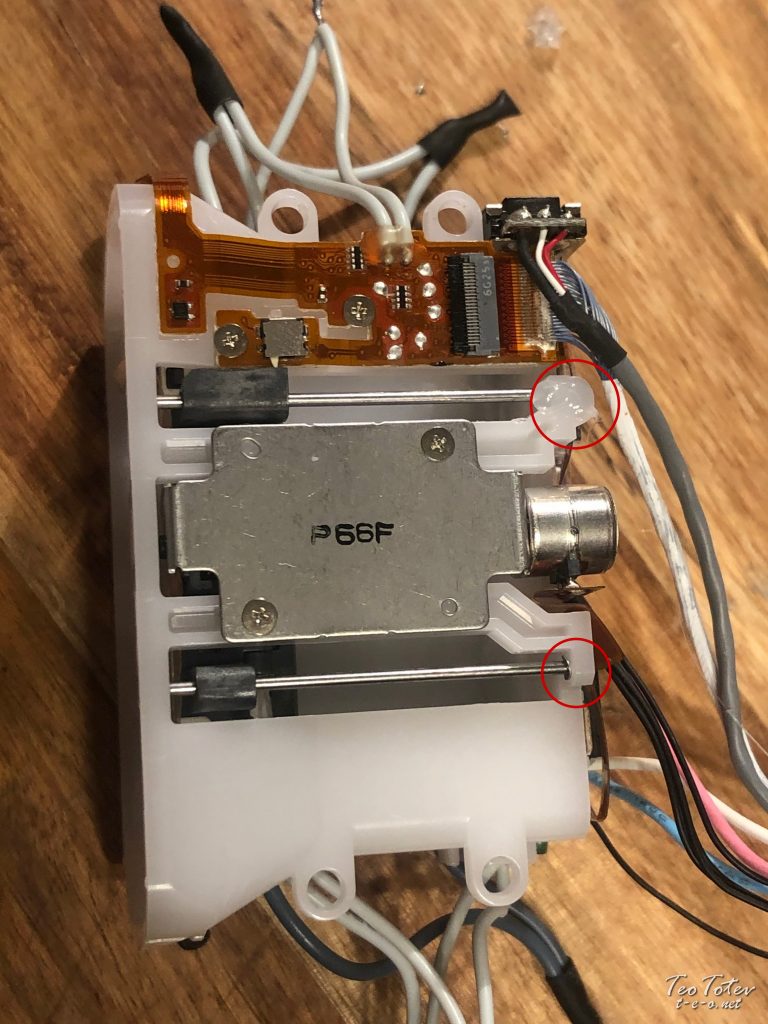

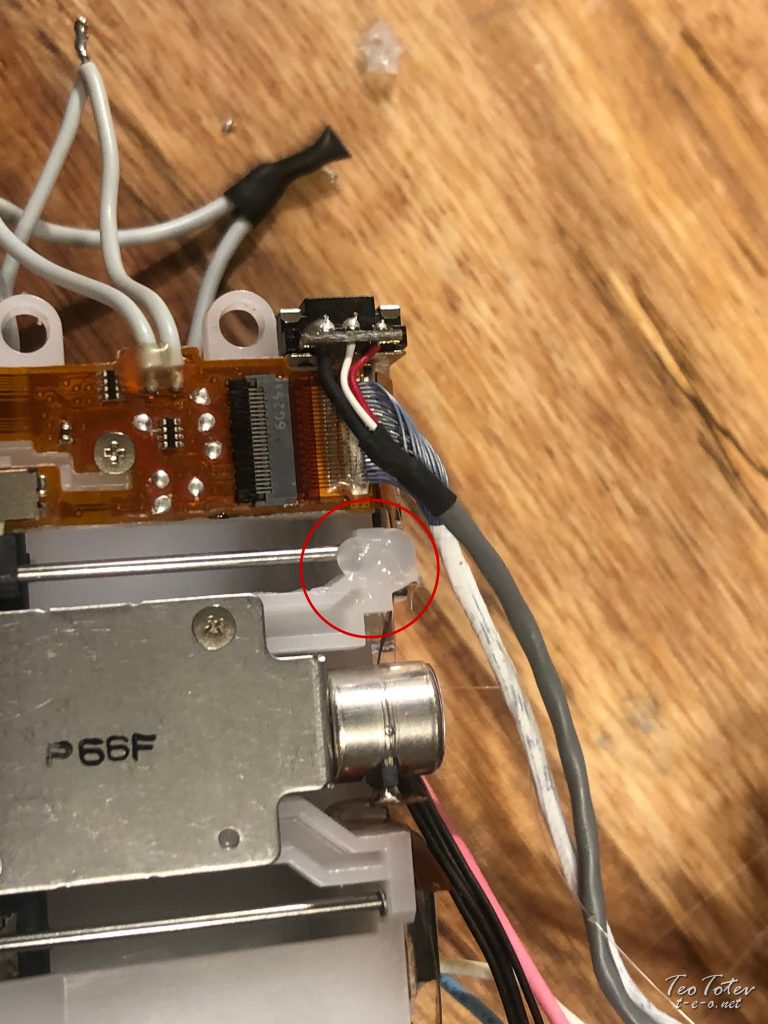

In top center you see where motor is pulling xenon tube assembly. Don’t forget to set it in same way with new tube assembly.

On right there is small sensor which is very fragile so be extra carefull with it.

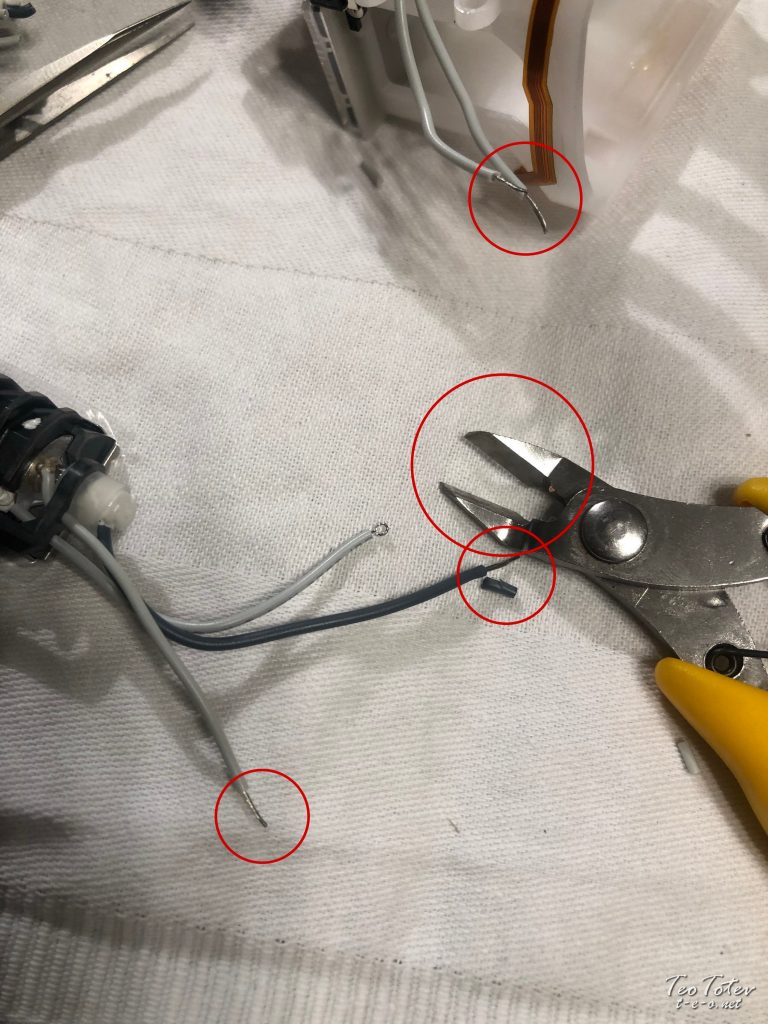

On bottom are 0.6mm e-clips which were very difficult for removal.

I used very small watch screwdriver to pull them, but unfortunately one of them become bend.

While I was trying to straighten it, it fly away and with its microscopic size it wasn’t possible to found.

So I was put between two choices:

– to wait few weeks for replacement

– to fix it in another way

I choose second option for which you can read below.

Here are these extra special 0.6mm e-clips #047 /part number BS810-047/ if you want to order them.

You can see how tiny is the e-clip compared to bolts and flash rubber seal.

Here you can see drive shafts and place where e-clips were placed preventing shafts from any moving or slipping.

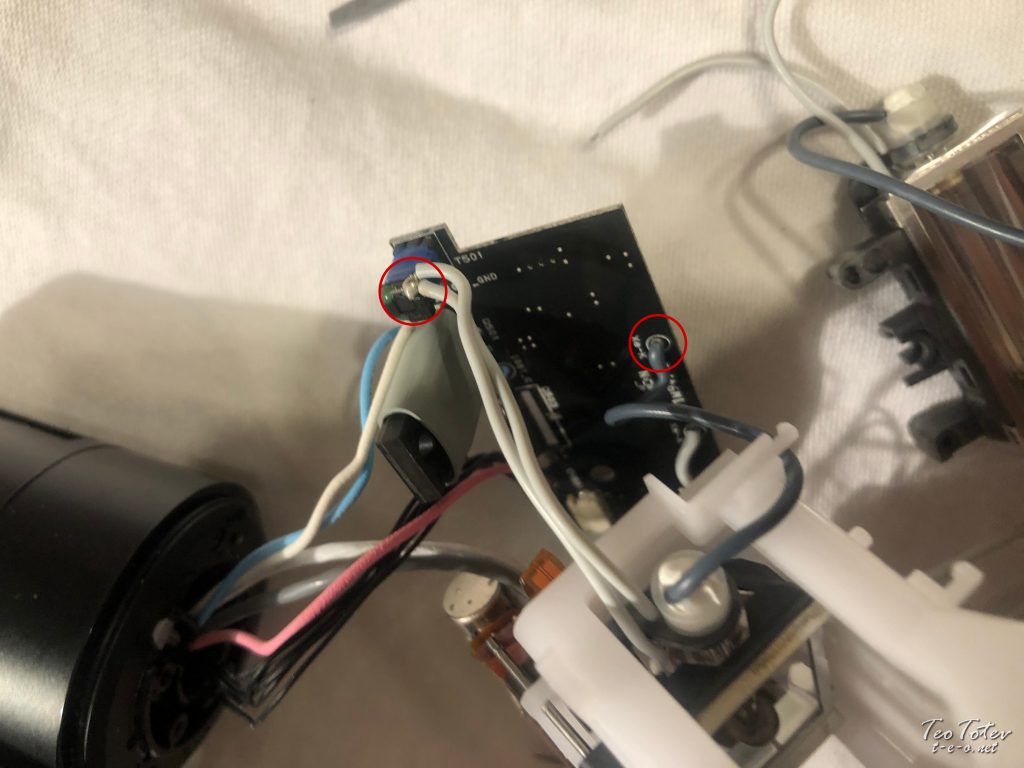

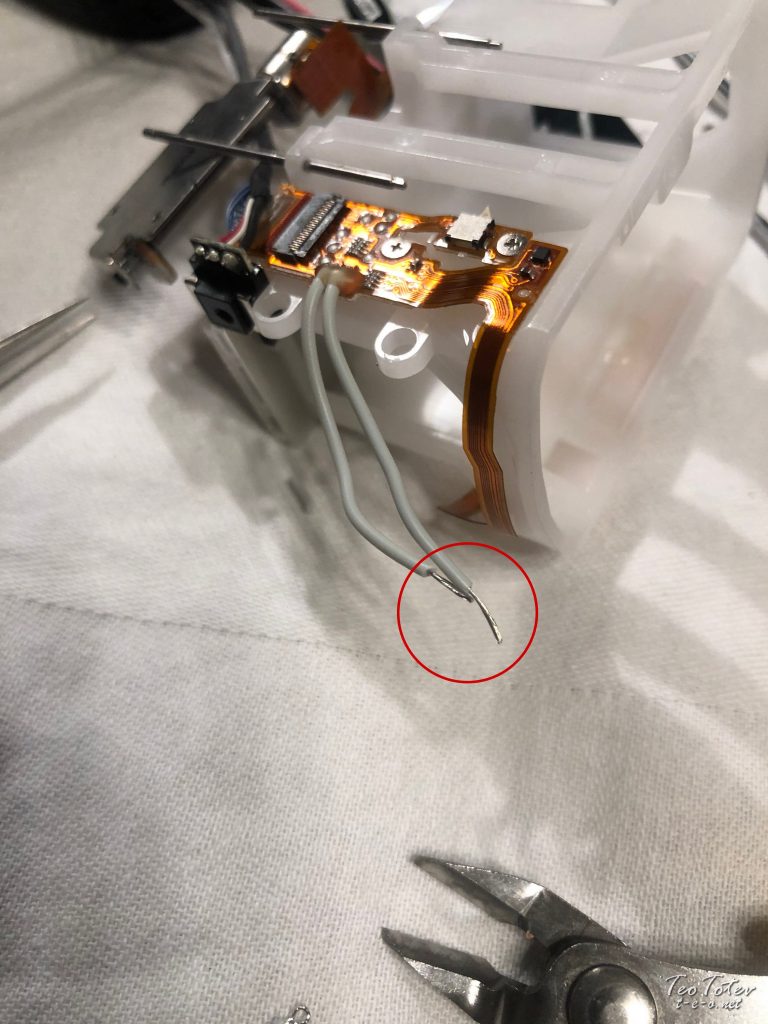

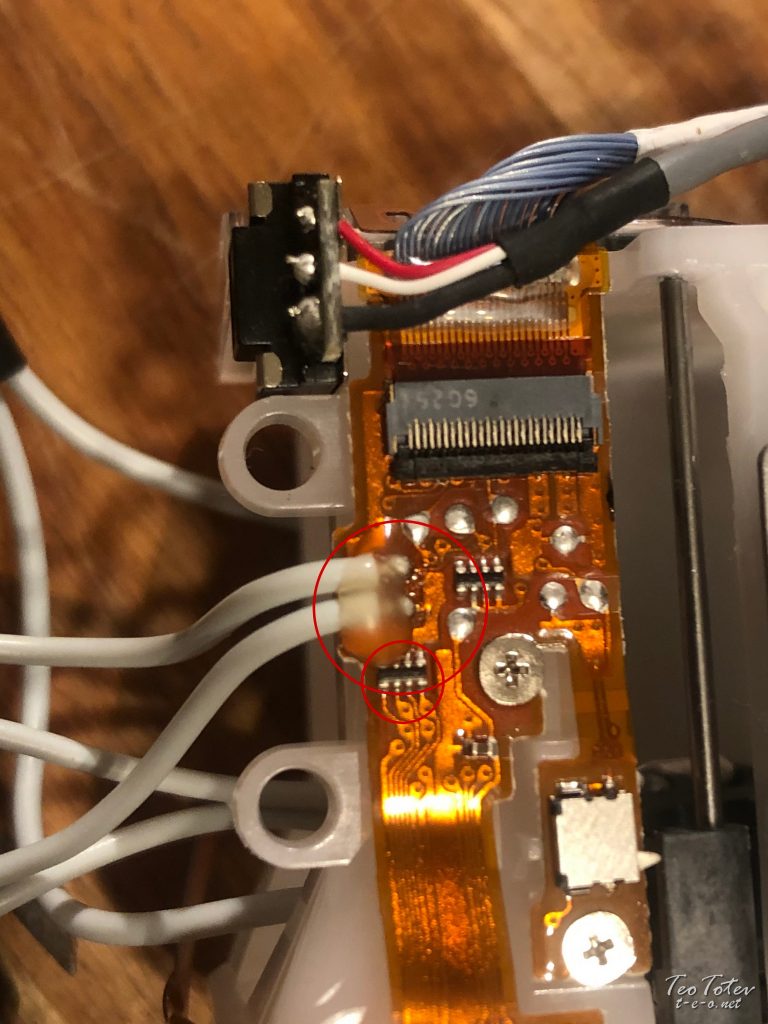

I took a photo so I can see later which was place where cables connect to PCB from flash tube.

Again, there are 3 cables on each side.

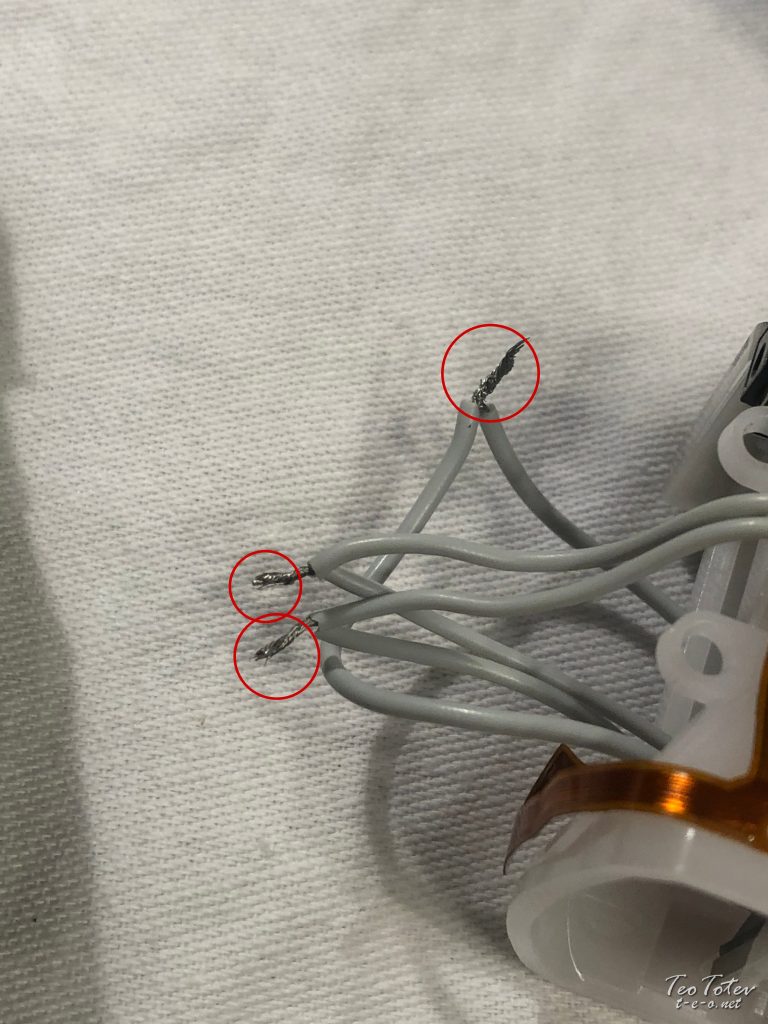

Already installed cables and comparison with ones in new flash xenon tube.

As you can see in middle of photo cables were soldered and glued next to very small chip.

So I decide not to solder them on PCB, but to strip cables and solder them on the side.

As if I damage this chip with heat it will be expensive to replace PCB also.

I used cable stripping tool to strip cables.

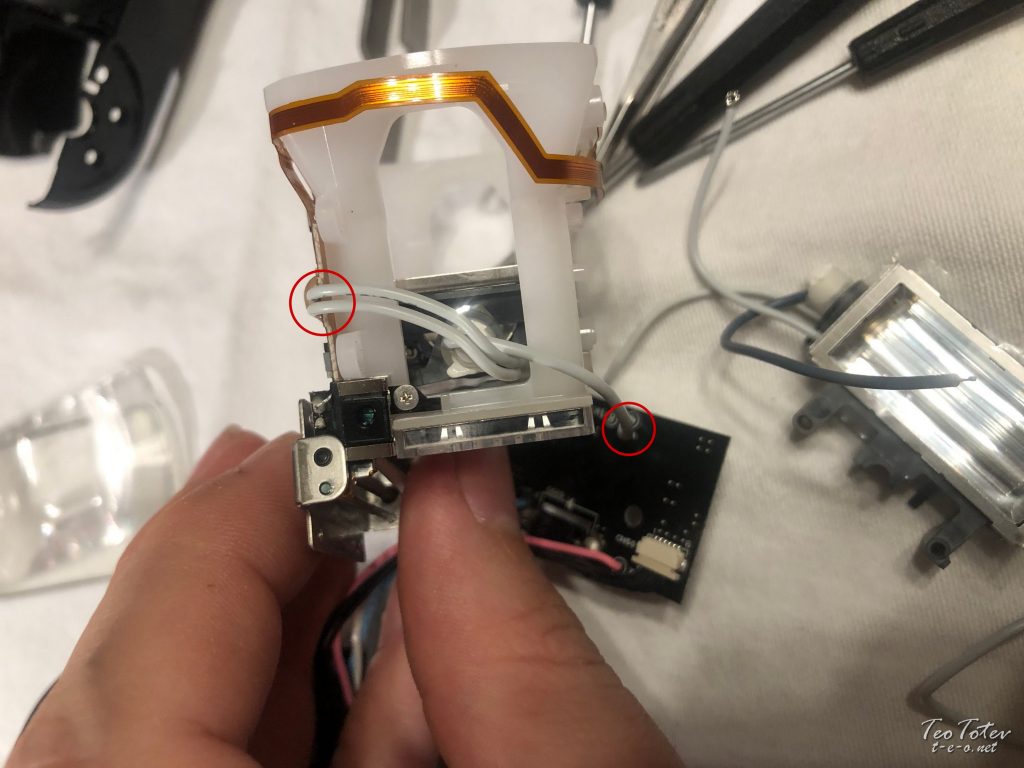

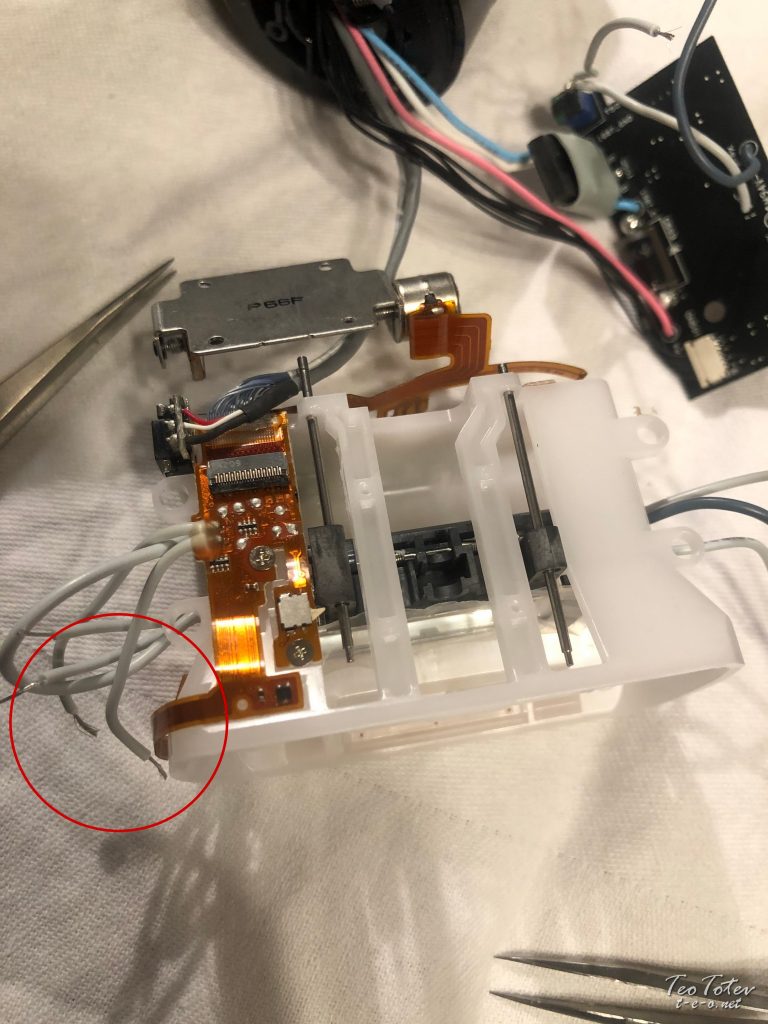

After I put new Xenon tube assembly on drive shafts I have left cables on side to connect.

This was most difficult part of Nikon Flash Tube Replacement.

To have secure connections I did first cable twisting with tweezers.

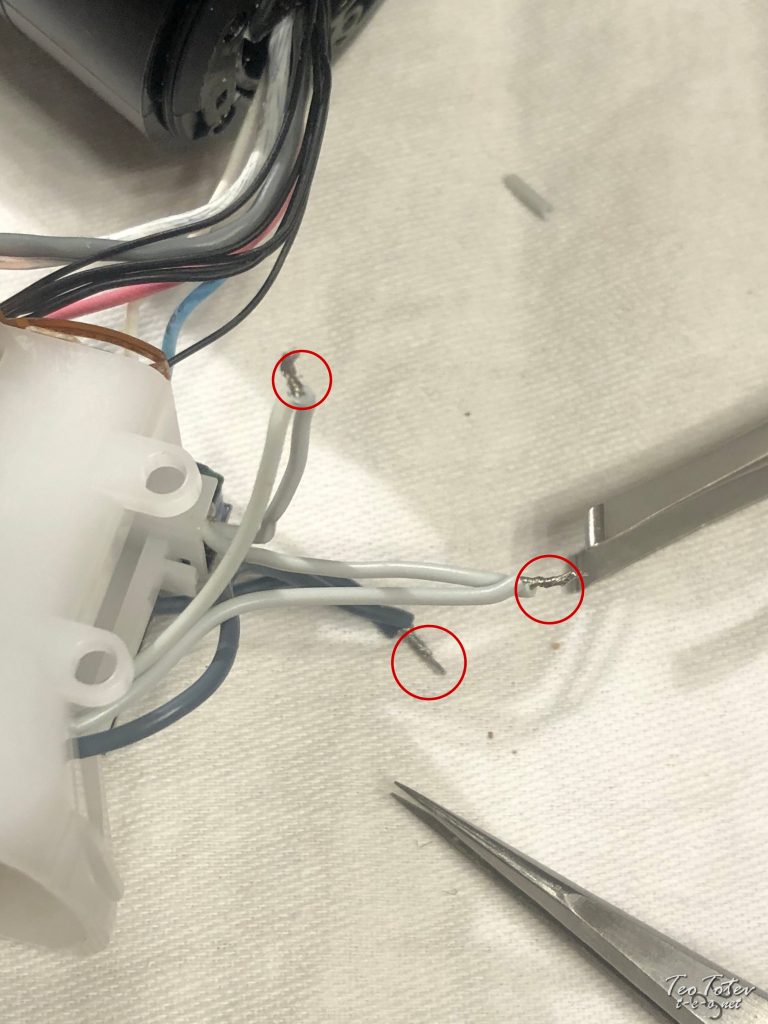

Here are all cables on one side ready for soldering.

Soldered Cables on one side.

Soldered cables on other side.

All soldering was done with Kester SN60PB40 solder. Good quality solder is making work very easy.

For audio connections I usually use solder with silver /Ag/ but it require high temperature to work so not best for sensitive electronics.

And my Weller EC2002M soldering station.

Here you can see most of tools which I used during repair of Nikon SB-5000.

Next step after soldering was to put heat shrinking tube on top of cable connections.

It is easy to be done if you hold tube/cables with big tweezers.

I forget to show this picture earlier, but this is why I choose to solder cable outside of board.

First there was glue on top of cables, and over really small chip.

So damaging it while removing glue and soldering was real danger.

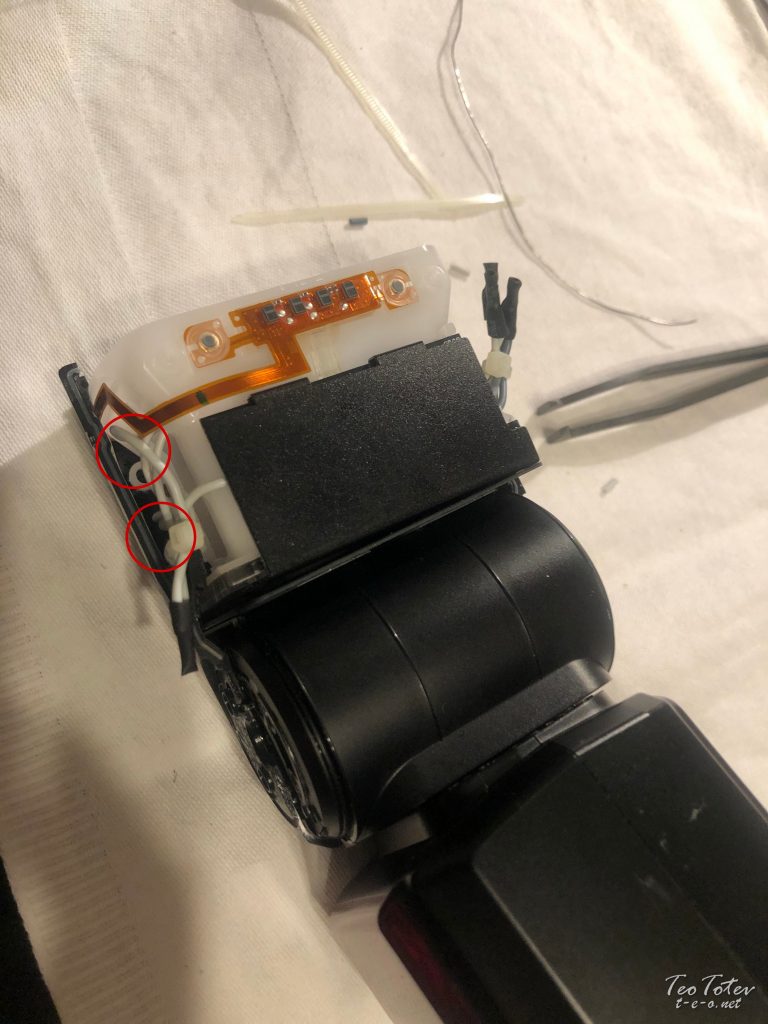

Here are heat shrinking tubes which I have pug on 3 of the cables connections.

And 3 cables from other side after soldering and covering with tube.

To fix drive shaft without missing 0.6mm e-clip I used hot glue.

I have applied it with Dremel 930 Dual Temperature hot glue gun.

I used lower temperature glue sticks and gun set at lower temperature.

Before I was using no-name Chinese glue gun, but it was very hard to make any precision put of glue with it, and Dremel 930 make a big difference.

Closeup of silicone /hot glue/ which I have put.

Next step was to use cable tie to hold cables together.

Here it is size of cable tie which I user for repair.

Don’t forget to cut cable tie to shortest possible length.

Assembly further was much easier.

Screw 2 screws on each side.

Put black metal divider behind flash.

These are special tweezers which I used for holding screws to put them in tight places.

Before putting back glass fresnel see which is correct way.

As even it looks same on top/bottom, side shapes are different and there is only one correct way you can assemble it.

So here it is glass fresnel slided in, back divider also in place and black plastic protector put on.

So from here there were only to put two screws on top, and 8 screws on side and flash was fully assembled back.

With this Nikon Flash Tube Replacement of my Nikon SB-5000 Speedlight have completed.

If you would like to find more and to see more of my photography work, please visit main part of my Website. For any queries and bookings please contact me. You can also find me on Facebook, Twitter or Instagram.

Very impressed with this repair work and how you have documented it. I came across the piece when I was researching Nikon Speedlights. I have not yet had a serious problem with mine – touching wood.

There is a white component with 2 green wires coming out of it. It is right under the white hood. So I accidentally connected both ends of the bulb and this component smoked. What is it and what does it do? And do I need to replace it? My bulb is broken. Will replacing the bulb and leaving this component as it is cause any problems?

Is there any labelling on white component? And did you have batteries in flash when you connected bulb?